How Does Industrial Ethernet Camera Enhance Connectivity? B, one of the most important strengths is its bandwidth. At 1 Gbps, Ethernet connections (e.g. GigE (Gigabit Ethernet)) can achieve such speeds and help industrial-grade Ethernet cameras transmit high-resolution images with real-time performance so that there is no bottleneck. This speed is essential when it comes to applications like machine vision as the camera must be able to capture and transmit high-quality images at high frame rates, often 60 FPS or more so that production lines, in turn, are not slowed down.

Distance: You also need to consider the distance. Ethernet cameras can transmit data over greater distance, even up to 100 meters without repeaters while keeping high image data integrity and quality. Which Them Perfect For Big Factories, Or Multifloor Installations Where Cameras Need To Be Located Away From The Control System. Power over Ethernet (PoE) can be passed through one of the cables, so you only need to run a single cable that carries both data and power, reducing the amount of cabling needed and helping to shield against installation costs.

Industrial Ethernet cameras also have less delay times as related to other connection types when it comes to latency. USB 3.0 cameras might delay some processing over longer distances, but Ethernet cameras transmit camera data more stably to ensure real-time data processing for your system. The result of this low-latency feature is high in robotics and automated inspection systems where synchronisation of timing is mission-critical for the operations themselves.

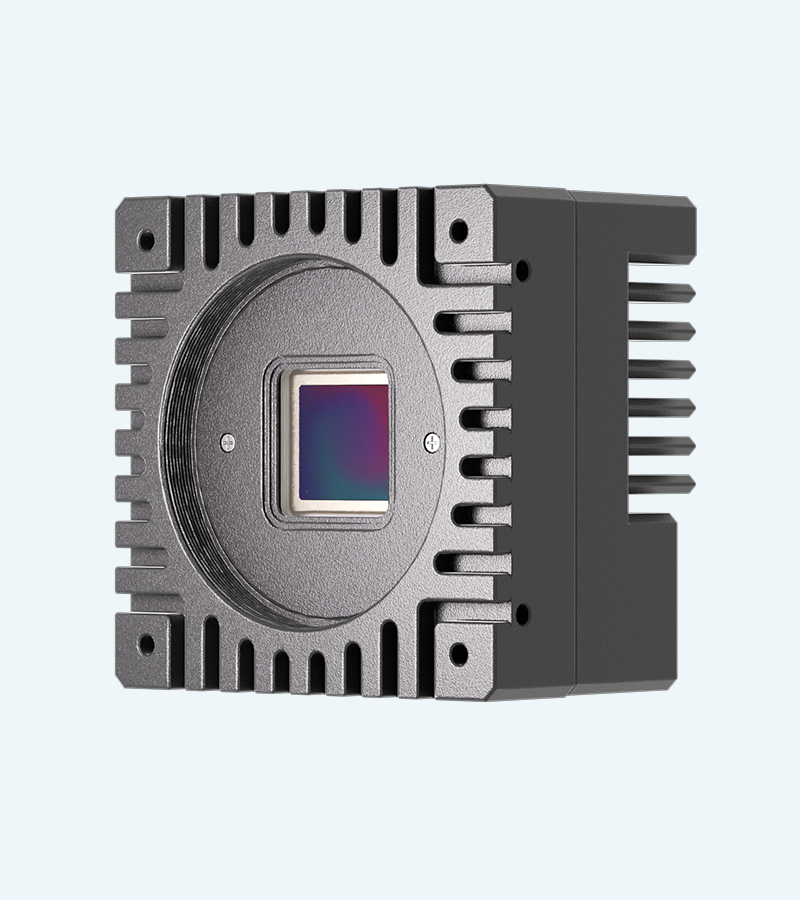

One of the biggest advantages is reliability. Industrial Ethernet cameras are constructed to withstand even the harshest of environments and maintain secure connections in difficult situations. Ethernet camera usually produced with ruggedized casings and many of them have an extended temperature range -20°C to 70°C, which has proven to be ideal for both car back sight cameras or food processing factories.

Meanwhile companies like Basler and FLIR have taken the lead in offering high-performance Ethernet cameras targeted for industrial applications. For example, Basler's ace GigE series or SONY block cameras are characterized by a long uptime and high level of robustness with MTBF (Mean Time Between Failures) ratings > 200,000 hours allowing for an extended lifetime without any maintenance intervals.

Ethernet cameras are critical for what Mark Delaney, an industrial-automation expert, says "is the heart of today's smart factories -- speed and scalability to collect and process real-time data". In essence, this statement reinforces the importance of Ethernet cameras in Industry 4.0 wherein connectivity plays a vital role for deploying machine vision systems into wider factory automation networks.

Cost efficiency is a consideration for companies that work to optimise production processes. The initial cost of Ethernet cameras tends to be higher than USB, but the convenience and stability in long-distance data transmission is invaluable for high-speed and high volume cameras used in large installations. They provide scalability too, as more cameras can be easily fitted into previously set-up networks without the need of enormous infrastructure changes.

Get a more detailed picture on high performance industrial ethernet camera options tailored to gathering connectivity requirements within harsh environments of industries.